Sustainability at Divilly’s

Pigmeat Quality Assurance

99% of Divilly's Pork Suppliers have PQAS programs in place

Recycling Programs

98% of Divilly’s Sliced cooked meats Base trays can now be recycled

Zero Waste to Landfill

Divilly’s have Zero Waste To Landfill

In 2022 Divilly’s became an Origin green Gold member

Origin Green is the worlds only national food and drink sustainability programme, enabling the industry to set and achieve measurable sustainability targets that respect the environment and serve local communities more effectively. It is a voluntary programme, led by Bord Bia, that brings together our food industry – from farmers to food producers, retailers to foodservice operators – with the common goal of sustainable food production.

Divilly’s is committed to sustainability and fully supports the collaborative nature of the Origin Green programme. We are verified members of Origin Green since 2018.

We continue to invest internally in our people, plant, processes and technology. In 2021 we invested in a state of the Art Slicing line. It delivers a higher performance cycle speed, low noise level, no compressed air, therefore No Compressed air exhaust in the packing room and less energy consumption.

For more information on Origin Green Visit: https://www.origingreen.ie/

100% of Divilly’s Sliced cooked meats base trays can now be recycled

100% of our suppliers have Food Safety/Quality programs in place

We achieved a 34% energy reduction in kWh/unit of output between 2018 and 2022.

We reduced our waste per unit of output by 16% between 2018 and 2022

99% of our Pork Suppliers have PQAS programs in place

Over 1000 meals supplied to Food Cloud over the past 3 years

Our Accreditations

Bord Bia

Approved under the Bord Bia Meat Processor Quality Assurance Scheme.

BRCS Food Safety Certified

Brand Reputation through Compliance

Department of Agriculture, Food and the Marine

Licensed under plant number IE 576 EC.

Proud verified member of Origin Green

Origin Green is a world leading national sustainability programme.

Divilly’s have pledged their commitment to reduce food waste by signing the EPA's Food Waste Charter

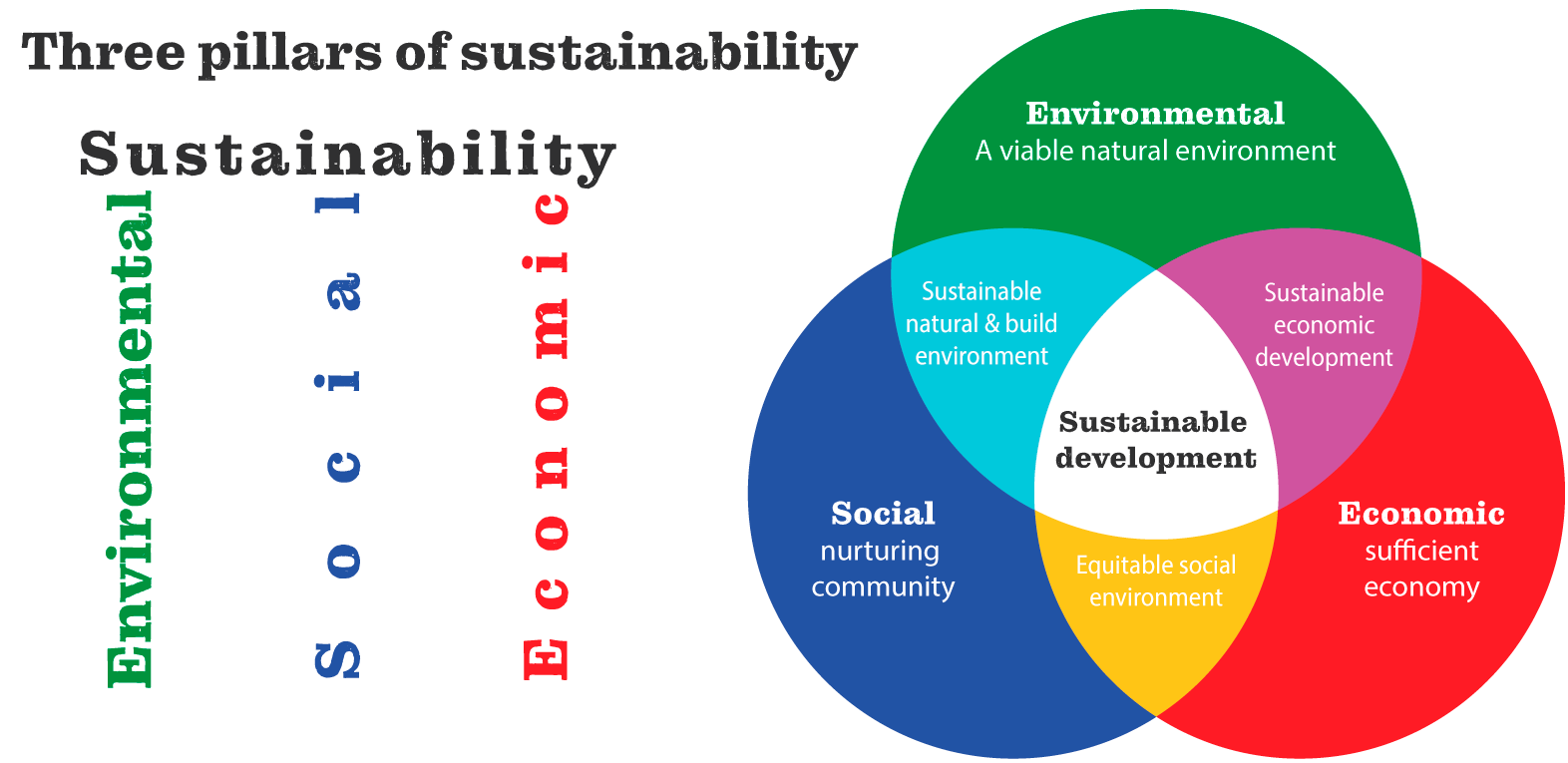

Social Sustainability

Divilly’s supports charities such as

- The Irish Cancer Society

- Jack and Jill Foundation

- Food cloud

- Various social clubs in the Connaught region